- Blog

Wendes Blog

Methods for calculating Ductwork Labor

There are several methods to calculate ductwork labor cost however, we will cover three of the most commonly accepted methods that provide consistent and accurate results are: The Hours per Piece Method, The The Hours Per Lb. Method and The Hours per Square Ft method for specialty ducts (PVC, FRP, Fiberglass, Flex etc.). The Hours Per Piece method is based on the actual amount of labor that is required to fabricate or install each specific piece and type of ductwork, predetermined and applied to the various sizes and types of ductwork in a takeoff. On this basis variations in the size and type of each piece of ductwork fitting and duct are considered as part of the labor calculation formula. This method is based on labor studies for the various types and sizes of ductwork fabricated and the experience of the estimators knowledge of the sheet metal fabrication process and associated labor and installation applied to the fabrication and installation of each piece. This is the most accurate method. Production labor studies and productivity rates are most often used as the basis for determining labor cost. The important consideration with this method is that labor will vary, in some cases significantly with variations in ductwork type and size. Productivity rates and per piece tables are shown in the Wendes Mechanical Estimating Handbook. SMACNA July 24 2024 to June 30 2025 uses a union wage rate range for local 103 of $55.94 per hr to $67.48 per hr for skilled sheet metal workers. The wage rate range varies by region and is applied to skill level for journeymen to senior level. By identifying the wage rate per region labor tables for productivity rates per piece fabrication and installation can be calculated.

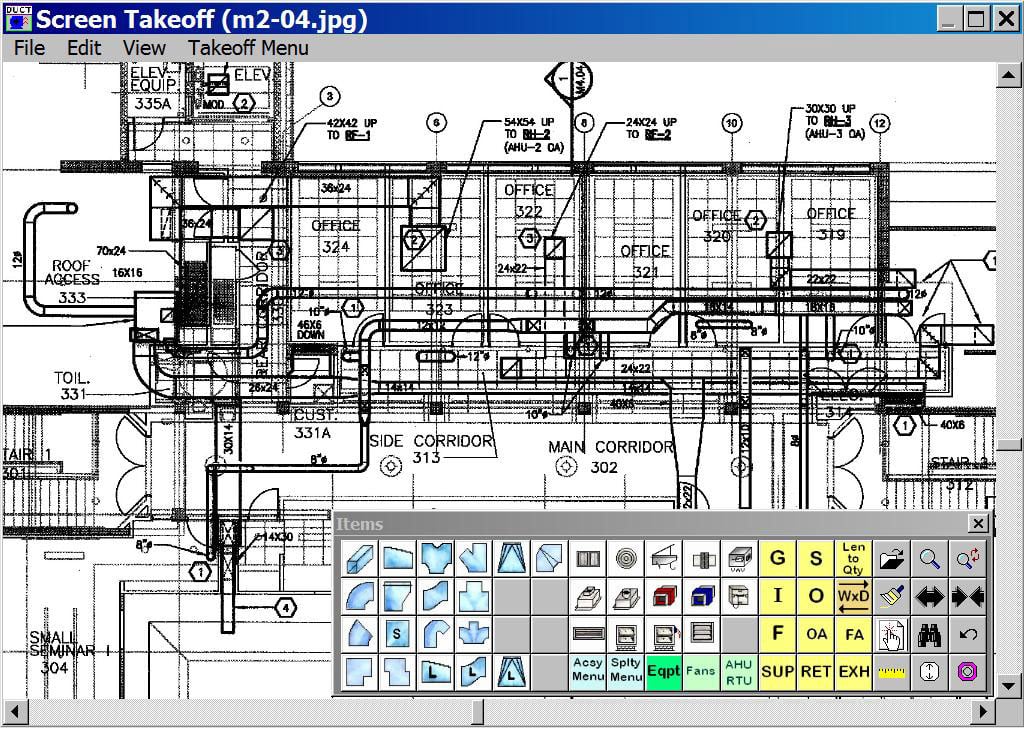

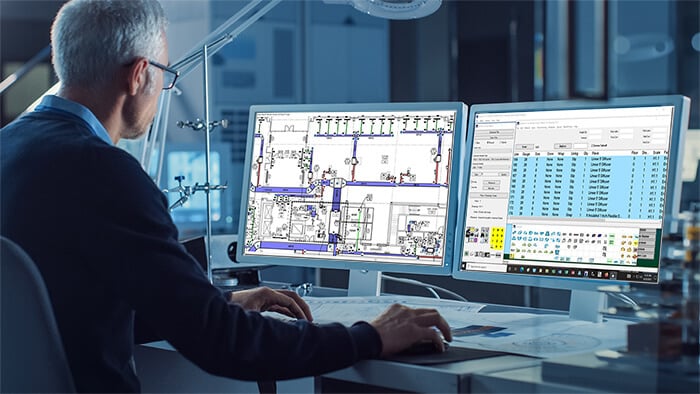

The Pounds Per Hour method for calculating labor is based on hours per pound of fabrication and installation labor productivity. As an example we will use a typical example of low pressure galvanized ductwork productivity at a rate of 44 lbs. per hour or " hours per pound" of ductwork fabricated or installed". If you use this formula you take 44 lbs per hour divided into 1=.023 hrs per lb. With this basic method an estimator can develop a formula for calculating shop labor. The Square Ft Per Hour Method is a useful way to compare labor cost for different types and gauges of ductwork as a direct comparison independent of per piece calculations or pounds per hour formulas. If you convert a typical 24 gauge low pressure galvanized ductwork productivity rate into square ft. using this formula you would calculate: 44 lbs per hour/1.156=38 square ft. per hour and install rate 25 lbs. per hour/1.156= 22 SF/hr. This basic formula can be used to cross check the hours per pound method and square ft. per pound method. The methods and examples provided provide a framework to assist estimators to quantify labor and material cost. Estimating Software includes tables for each method defined by the user. Automating Material and Labor Takeoff when using estimating software will provide a detailed listing of all materials used in a project based on project specifications. The information contained in takeoff will be broken out into various report categories with extensions and summary of the takeoff.