- Blog

Wendes Blog

HVAC Mechanical Estimating and HVAC Piping Estimating

Posted by

Joseph D'Amelio on Fri, Sep 23, 2011

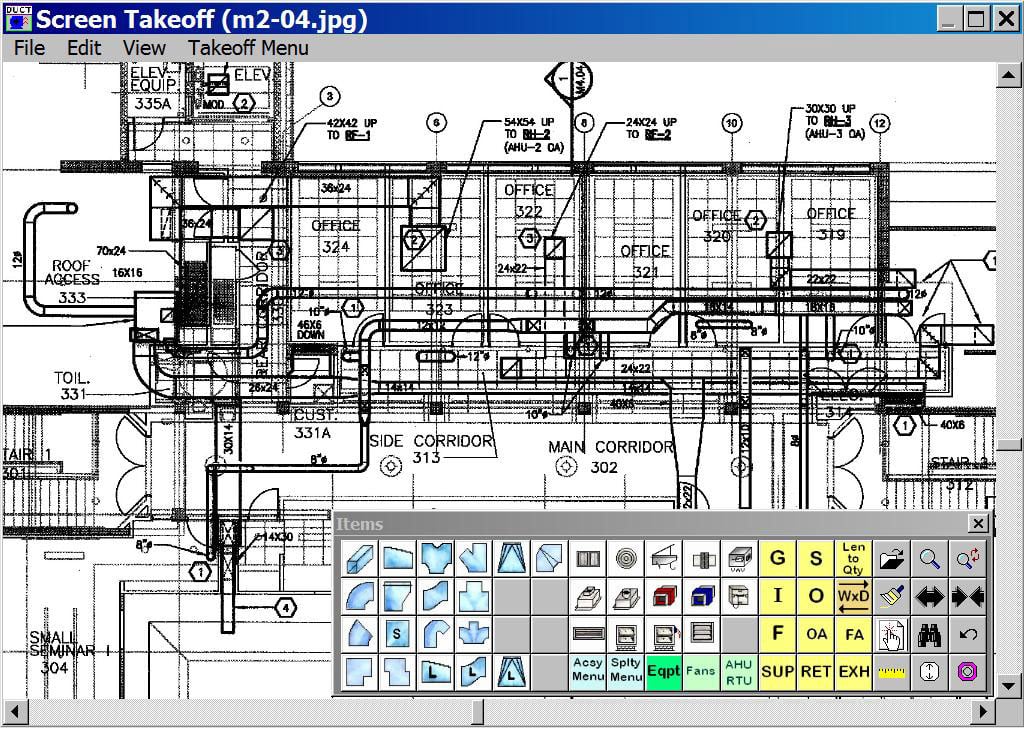

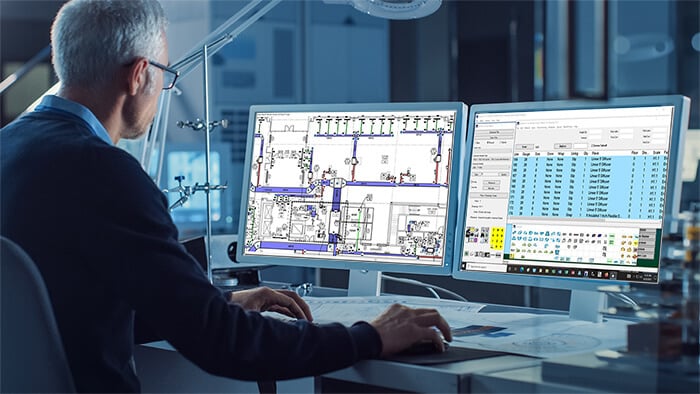

Estimating is described as the process of approximating unknown parameters using measured and empirical data that has a random component. In the case of HVAC Estimating Software as it is relates to HVAC Sheet Metal Estimating, HVAC Mechanical Estimating and HVAC Piping Estimating the objective is to accurately calculate labor and materials based on measurable project specifications. The random component in estimating a project accurately involves detailing the many specifications for a project and applying the appropriate labor and material component.

The labor hours contained in the Wendes HVAC Sheet Metal Estimating Software labor tables are based on 20 years of detailed time and motion studies conducted by Herbert Wendes. Wendes labor estimating hourshave been refined and validated by feedback ...

Read More

Recent Blog Posts

August 16, 2025

July 7, 2025