- Blog

Joseph D'Amelio

Recent Posts

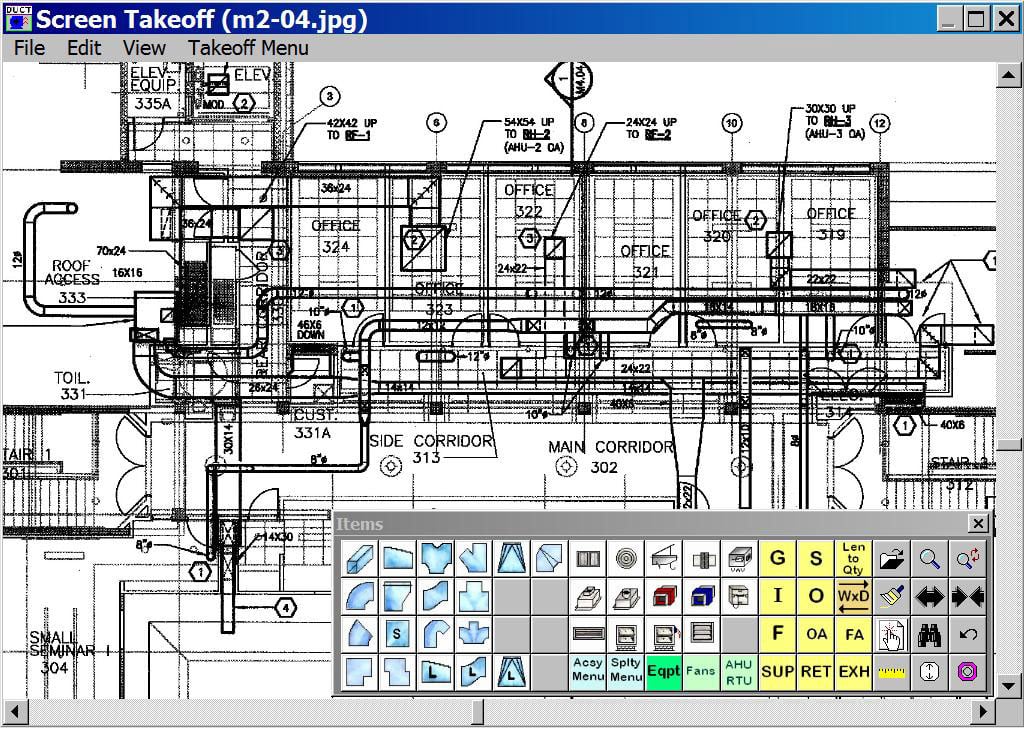

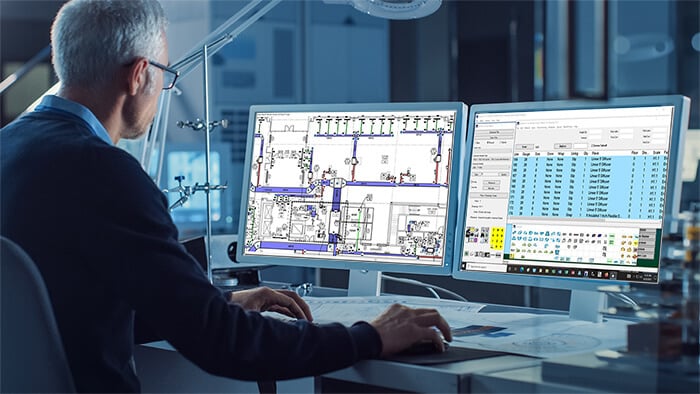

The Benefits of Using HVAC On-Screen Takeoff Software

Takeoffs are an essential part of any bid. While performing a Mecahnical Estimate ductwork takeoff is necessary, it can also be time consuming, and errors can be costly. Consider importing a digital PDF drawing file and complete a bid with Mechanical Estimating Software and On Screen Takeoff to save hours of labor and provide a paperless transfer of information. Update information and track projects, change orders and transfer information to the field digitally.

The Benefits of Using HVAC On-Screen Takeoff Software Takeoffs are an essential part of any bid. While performing a ductwork takeoff is necessary, it can also be time consuming, and errors can be costly. Consider importing a digital PDF drawing file ...

Read More

Boost efficiency with these important estimating functions. The most important factor that will increase estimating efficiency is improving the speed and accuracy of your takeoff. Now with the ability to import PDF and other drawing formats On-Screen...

Read More

Accurate Estimates are Crucial Whether putting together an estimate for potential customers who are interested in your HVAC services, or calculating the overall requirements of a construction plan – precision outperforms guesswork every time. Accurat...

Read More

HVAC Takeoff Software will help you win bids by improving the accuracy of your labor and materials costs. Estimating software will create an extensive database of your project history and can easily be modified as the scope and specifications for a p...

Read More

Recent Blog Posts

August 16, 2025

July 7, 2025